Overview

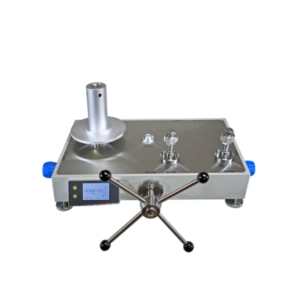

Pressure is defined as the ratio of force applied over a given area to that area. The HSIN-6 hydraulic piston dead weight tester employs a highly accurate piston system, which generates the required pressure for measurement by loading weights onto the component. The piston cylinder and rod are fabricated from tungsten carbide, a material known for its minimal pressure deformation and low thermal expansion coefficient. This ensures excellent linearity of the piston’s cross-section, thereby enhancing the instrument’s accuracy.

The HSIN-6 hydraulic piston dead weight tester directly measures pressure using the fundamental definition (P=F/S). The use of high-quality tungsten carbide in the piston system minimizes measurement uncertainty and ensures long-term stability exceeding 5 years.

Feature

- The patented piston pressure system features a novel structure with anti-collision design, tool-free disassembly, easy cleaning of the piston system, and convenient, rapid, and safe replacement of the seal ring.

2. Compact and lightweight piston systems have been successfully developed and tested, now in production. These systems are more convenient to use, significantly reducing labor requirements. Customers can choose based on their specific needs or consult via telephone.

3. Piston displacement data is acquired using two infrared ranging sensors, processed through a custom-designed circuit system, and displayed on an LCD screen for accurate and convenient observation.

4. The piston display system utilizes a 3.5-inch touch color screen that shows piston rod displacement, ambient temperature, and humidity.

5. Equipped with two quick-connectports(M20×1.5) and an optional isolation valve, suitable for sealing tests.

6. An optional table block globe valve is maintenance-free and easy to operate, with a handle designed ergonomically for comfortable handling.

7. The main body is constructed from 12mm thick aluminum alloy sheet, ensuring robustness and stability. The oil cup has a capacity of 400ml and can be customized for larger sizes upon request. It facilitates calibration of multiple sensors and includes an oil filter device. The pipeline directly connects to the oil cup via a sewage filtration system, ensuring clean oil enters the piston system, preventing contamination and damage, and avoiding piston rod jams or breakage.

8. The oil system incorporates a sewage discharge function, simplifying maintenance and cleaning processes.

9. The piston display unit includes touch switches and a displacement calibration button. Quick instructions for displacement calibration can be accessed on the screen, enhancing ease of use for customers.

Technical Parameter

| Model | HSIN-6 | Range | (0.06~0.6)MPa | Main Material | |

| Accuracy | 0.005/0.01 0.02/0.05 |

Body Dimension (L*W*H)mm |

680*480*310mm | Rod | Cylinder |

| Weight(Kg) | 26 | Body Material | aluminium alloy sheet | tungsten carbide | tungsten carbide |

| Media | 25# transformer oil mixed with aviation kerosene

At 20℃, the kinematic viscosity is 9~12, and the acid value is not more than 0.05mgKOH /g.

Ratio 4.29 (25# transformer oil) : 1 (aviation kerosene) |

||||

Weight Configuration

| Specifications(MPa) | Quantity(piece) | Size diameter Φ(mm) | Mass(Kg/piece) | Material |

| 0.05 | 10 | 135 | 0.5 | stainless steel |

| 0.01 | 4 | 108 | 0.1 | aluminum |

Use Environment

1.Environment Temperature:(20±1)℃

2.Relative humidity: Thermostatic chamber below 85%

3.Power supply voltage: AC 220V

4.Frequency: 50Hz

5.There shall be no mechanical vibration affecting the metering performance during use.