Overview

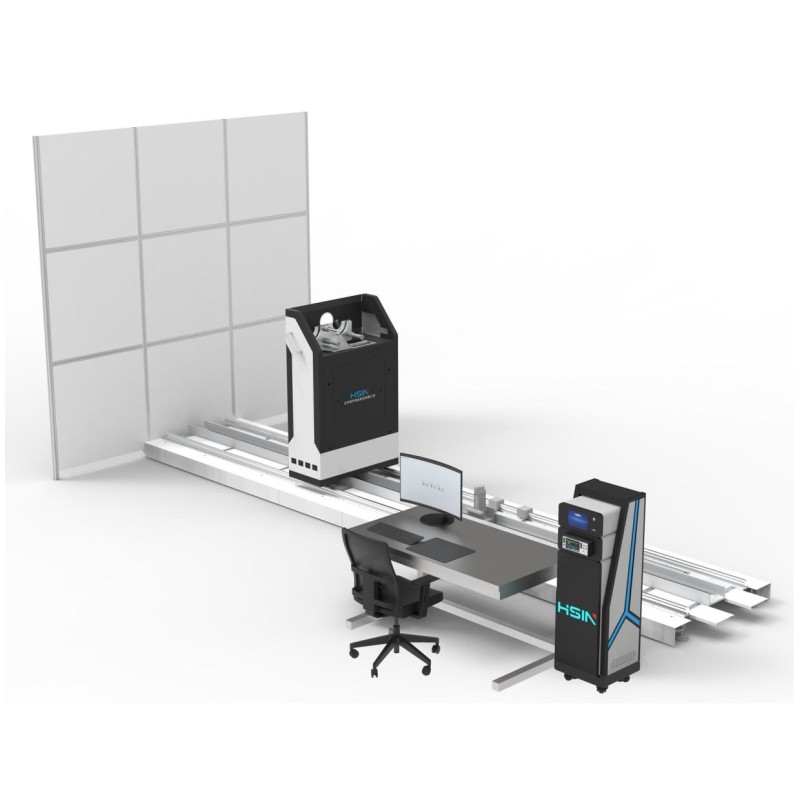

HSIN8020 analog method liquid level meter calibration device is primarily designed for non-contact liquid level meter calibration. It integrates a main control system, linear track, test vehicle, reflective target, electric drive system, and automatic control software into a single unit. The control system precisely regulates the liquid level, while the measurement system accurately measures it. Combined with specialized software, this setup enables automated testing and the generation or printing of certificates. This device finds extensive application in metrology institutes, scientific research facilities, and calibration laboratories across various industries.

Technical Parameter

- Measuring Range: Customizable according to customer requirements, with a maximum range of 50,000mm. Recommended ranges include 0 ~ 10,000mm, 0 ~ 15,000mm, and 0 ~ 20,000mm.

2. Accuracy Levels: Available options are 0.01%F.S., 0.02%F.S., 0.05%F.S., and 0.1%F.S.

3. Standard and Accuracy: Grating displacement movement platform accuracy levels are 0.01%F.S., 0.02%F.S., and 0.05%F.S.

4. Measuring Interface: Customizable, including flanges up to DN200 or thread connections of any size.

5. Digital Signal Acquisition Interface: Options include USB-B, LAN, or RS232.

6. Analog Signal Acquisition Type: Supports 4 ~ 20mA and 0 ~ 10V signals with an accuracy of ±0.02%.

7. Reflector: Customizable, standard sizes are 3.6m×3.6m and 5.2m×5.2m.

8. Installation and Replacement: Designed for quick installation and fastening by a single person.

9. Control Accuracy: Achieves ±0.01mm and ±1mm precision.

10. Levelness Positioning Control Requirements: Levelness projection angle ≤10°.

11. Control Cabinet: Contains terminal display, power supply system, control system, and electrical measuring instruments.

12. Operation Mode: Supports both automatic and manual modes, which can be freely switched.

13. Compliance: Adheres to JJG971-2019 liquid level meter verification regulations, automatically generating original records and certificates in accordance with the recommended format.

Feature

- Multiple devices can be inspected simultaneously without interference between two non-contact liquid level meters. For non-contact level gauges that may interfere with each other, the system automatically switches and verifies them sequentially.

- The device features automatic zero search functionality, where it automatically locates the signal zero position based on the parameters of the level gauge.

- Safety start-stop technology ensures operational safety by automatically stopping if someone enters the moving range of the test vehicle during automatic detection. Detection resumes automatically once the area is clear.

Calibration

HSIN8020 can calibrate kinds of liquid level instrument such as non-contact radar level meters, ultrasonic level meters, and other similar instruments.

Working Principle

Main Structure

The guide length is ≥ actual measuring range + 500mm, ensuring precise levelness and linear displacement positioning with straightness of 5/10,000mm. The drive motor and displacement adjustment components achieve an accuracy of ±0.002mm. Installation parts are made from stainless steel with flange connectors ranging from DN15 to DN200.

Reflection Target

The reflector uses a carbon material and silica gel mixed carrier, with a microwave reflection angle ≤3° and a dielectric constant of 5.6 ~ 12. Depending on the actual situation, the foot and wall-fixed design saves space.

Displacement

As a standard, the overall accuracy of the grating displacement movement platform can reach 0.01%F.S.

Straightness Positioning

For measuring meter positioning and tooling adjustment, aluminum alloy is used with a levelness angle ≤1°. Standard levelness positioning also maintains a levelness angle ≤1°. The displacement adjustment component is positioned horizontally with a horizontal angle less than 1°. The reflector is positioned perpendicularly to the measurement reference line with a levelness angle ≤1°.

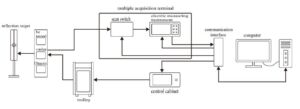

Signal Acquisition

Signal acquisition ports include USB-B, LAN, or RS232, supporting (4 ~ 20)mA and (0 ~ 10)V signals with an accuracy of 0.05%F.S.

Software

The system automatically generates original records and certificates in compliance with <JJG971-2019 Liquid Level Meter Verification Regulations>.